Services

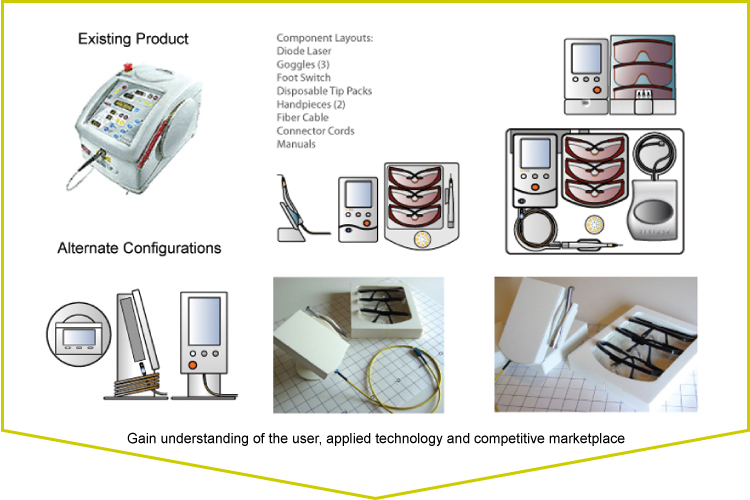

Technical and Marketing Analysis

Understanding your product, the intended user and where you want to take it.

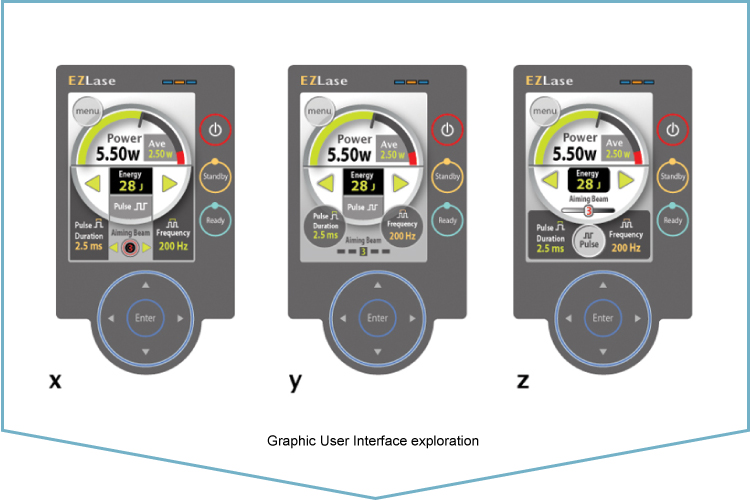

Concept Exploration and Refinement

Loose sketches and quick mockups are used to explore a wide range of functional and aesthetic possibilities. The best concepts move on to refinement.

CAD Modeling and Rendering

Integration of form & components and problem-solving using industry standard programs (SolidWorks) for 3D modeling and photorealistic visualization.

Part Design

Part design and assemblies for 3D printing, prototyping, material selection and manufacturing processes.

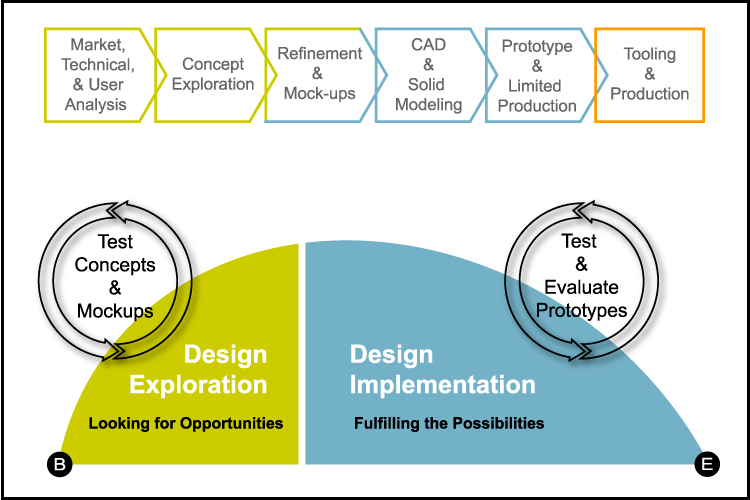

Process

The design process follows an arc of activity that begins with the exploration of design concepts based upon market opportunities, technical and user criteria. The best solutions from this work are refined, tested and transformed into working prototypes before the design moves on to production. Our methodical, phase by phase approach breaks the project down into a series of achievable milestones that keep the work focused and the client informed of our progress. The following case study takes us through the steps of our collaboration with Biolase to develop the EZ Lase Dental Laser System from concept to CAD files.